Guangzhou Suncar Seals Co., Ltd.

- Guangzhou Suncar Seals Co., Ltd. is a foreign trade company

specializing in construction machinery seals. Suncar has a complete

management center, professional product consulting services,

innovative research and development of product production,

efficient logistics and distribution and other organizational

structures. At present, the company's business covers many regions

at home and abroad.

- Suncar Seals entered the construction machinery oil seal industry

in 2008 and has nearly 12 years of oil seal technology experience.

Suncar Seals has always maintained its core technology advantages,

advanced manufacturing and processing capabilities, scientific

management system and complete after-sales system. It is recognized

as one of the most promising companies in China's future mechanical

oil seal business.

- Suncar Seals has a wealth of experience in production and

processing and a good production environment. Product is used for

excavators, bulldozers and wheel loaders of Komatsu, C.A.T, JCB,

Hitachi, Sumitomo, Kobelco, SUNCARVO.L.VO, KATO, Daewoo, CASE, John

Deere and other brands.

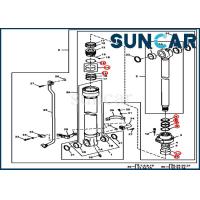

- Suncar Seals company provide construction machinery equipment such

as loaders and crawler excavators provide high-quality,

high-performance, long-life seals and vehicle parts, which solves

the problem of maintenance and replacement of construction

machinery parts for customers. Relying on its good reputation in

the machinery industry, SUNCAR will always maintain its original

intention, actively develop and create a unique brand belonging to

the company, and provide customers with high-quality products at

lower costs, better quality and good service.