490 JOHN DEERE AT196477 Boom Hydraulic Cylinder Service Kit

Excavator Repair Seal Kits

| Product Name | John Deere Boom Hydraulic Cylinder Service Kit |

| Models | John Deere 490 |

| Part Number | AT196477 |

| Material | PU, Rubber, PTFE, NBR, HNBR, ACM, VMQ |

| Place of Origin | China(Mainland) |

| Brand name | SUNCAR |

| Packing | PP bag inside, carton box outside |

| Shipping Mode | By air, by sea, by express(FedEx, UPS, DHL, TNT, etc.) |

| Payment Terms | Western Union, L/C, T/T, D/A, D/P |

| CertifiC.A.Tion | ISO9001 |

| Warranty | Unavailable |

| Customized | OEM & ODM are welcomed |

| Size | OEM standard size |

| Position | Hydraulic cylinder seal kit |

| Condition | New, genuine new |

| Feature | Sealing performance/ wear resistance |

| AppliC.A.Tion | Boom |

When You Open And Repair The Cylinder, Please Follow Below

Operation:

1. Take off the cylinder from the machine.

2. Remove the head assembly and the rod assembly from the stick

cylinder group.

3. If it always happens that the seal kit not perform well soon

after it fitted, there maybe problem of the cylinder assembly

itself. It is better to check the cylinder assembly whether need to

change it.

4. Measure the seal kits before fitting.

5. Install the seals: after fix the cylinder assy, test it first

before re-install the stick cylinder group on the machine.

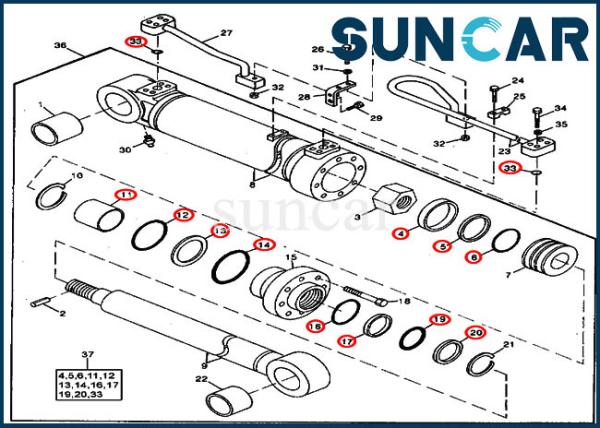

Parts On Group Boom Cylinder:

| Pos. | Part No | Qty | Parts name |

| 1 | 207602 | [1] | Bushing |

| 2 | 34M7133 | [1] | Spring Pin |

| 3 | 207610 | [1] | Nut |

| 4 | TH100149 | [2] | Wear Ring |

| 5 | TH100150 | [1] | Seal |

| 6 | TH100151 | [1] | O-Ring |

| 7 | 207633 | [1] | Piston |

| 7 | 207634 | [1] | Ring |

| 8 | 207601 | [1] | Hydraulic Cylinder Barrel |

| 9 | 207605 | [1] | Rod |

| 10 | 207615 | [1] | Snap Ring |

| 11 | TH100158 | [1] | Bushing |

| 12 | TH100156 | [1] | O-Ring |

| 13 | TH100157 | [1] | Back-Up Ring |

| 14 | AT264320 | [1] | O-Ring |

| 15 | 207612 | [1] | Hydr. Cylinder Rod Guide |

| 16 | TH100160 | [1] | O-Ring |

| 17 | TH100159 | [1] | Seal |

| 18 | 207621 | [8] | Screw |

| 19 | TH100161 | [1] | O-Ring |

| 20 | TH100162 | [1] | Seal |

| 21 | 207620 | [1] | Snap Ring |

| 22 | 4657238 | [1] | Bushing |

| 23 | 207622 | [1] | Tube |

| 24 | 19M8261 | [2] | Cap Screw |

| 24 | 12M7056 | [2] | Lock Washer |

| 25 | 207630 | [1] | Half Clamp |

| 26 | 19M7363 | [2] | Cap Screw |

| 27 | 207623 | [1] | Oil Line |

| 28 | 207625 | [1] | Bracket |

| 29 | 19M7268 | [2] | Cap Screw |

| 30 | TH100074 | [1] | LubriC.A.Tion Fitting |

| 31 | 12H301 | [4] | Lock Washer |

| 32 | TH100169 | [2] | Nut |

| 33 | AT264333 | [2] | O-Ring |

| 34 | 19M8711 | [8] | Screw |

| 35 | 12M7056 | [10] | Lock Washer |

| 36 | AT264205 | [1] | Hydraulic Cylinder |

| 37 | AT196477 | [1] | Seal Kit |

Measures For Oil Leakage Due To Inadequate Oil Seal:

1. Master and recognize the basic knowledge of fake and inferior

products, and purchase high-quality and standard oil seals.

2. During installation, if the roughness of the outer surface of

the shaft diameter is low or there are defects such as rust, burrs,

etc., smooth it with a fine emery cloth or whetstone; apply clean

engine oil or grease to the lip of the oil seal or the

corresponding position of the shaft diameter. Apply sealant to the

outer ring of the oil seal, wrap the key way on the shaft with hard

paper to avoid scratching the lip of the oil seal, and use a

special tool to rotate and press the oil seal inwards. Do not smash

the hard seal to prevent deformation of the oil seal or squeeze the

spring and fail; If there is lip cuffing, the spring falls off and

the oil seal is skewed, It must be removed and reinstalled. It

should be noted that when the shaft diameter is not worn and the

spring force of the oil seal spring is sufficient, do not tighten

the inner spring without authorization.

3. The oil seals applied to machinery generally have to be

inspected, maintained and maintained when the general working

conditions are poor, the ambient temperature difference is large,

the dust is excessive, and the vibration of the machine tool

frequently changes the stress condition of the machine parts.

4. If the shaft diameter and bearing are seriously worn; The rubber

seal oil is aging or the spring is invalid, etc., repair and

replace the corresponding parts in time.

Product Show: